DYD - Polyurethane Insulated Panel Technical Specifications and Data

DYD - Polyurethane Insulated Panel Technical Specifications and Data

DYD – Polyurethane Insulated Panel Technical Specifications and Data

Technical Advantages and technical specifications to be used

- Best heat & cool insulation materials

- Rigid and light weight

- Environment friendly materials

- Water, Moisture and Sound proof

- Easy and simple construction design

DYD — Polyurethane Insulated Panel based on hot-pressed high density Technical Specifications

DYD — Polyurethane Insulated Panel based on hot-pressed high density Technical Specifications

DYD — Polyurethane Insulated Panel based on hot-pressed high density Technical Specifications

| Core | Polyurethane (P.U.) Foam |

| Density | 40 ±kg/cu. M |

| Blowing Agent | HCFC 141b until 2015, Cyclo-Pentane |

| Skin ;

Plain or Corrugated type

|

1) Polyester Resin Coated G.L. (Galvalume) and G.I. (Galvanized Iron)

2) PVDF 3) Plastisol (PVC) 4) ABS sheets with 1.5 mm and 2.0mm Thickness 5) Stainless steel 304 Aluminum, Cement boards are available by requirements |

| Thermal Conductivity | 0.1016 k Cal / m h ºC |

| Effective Width | 900 mm W and 1200 mm W |

| Length | Small Bed = 900/1200 mm W x 3,500 mm L |

| Medium Bed = 900/1200 mm W x 6800 mm L | |

| Large Bed = 1200 mm W x 11.700mm L | |

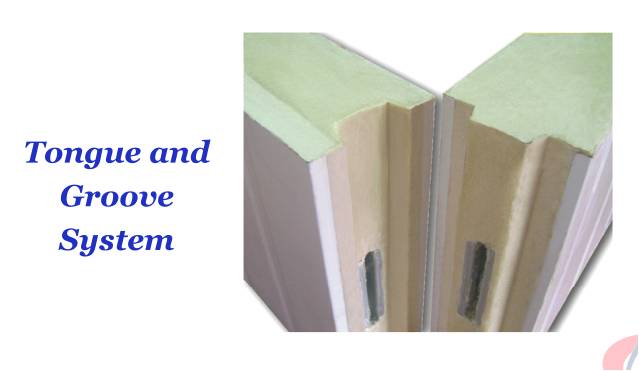

| End Connection | Tounge and groove / plain |

DYD — Polyurethane Insulated Panel Connection Structure System

DYD — Polyurethane Insulated Panel Connection Structure System

DYD — Polyurethane Insulated Panel Connection Structure System

-Plain type skin and Corrugation type skin connection with Tongue & groove (male and female)

-Corner wall (using for IQF freezers and Cell site cabin only) and Cam-lock fastener connection

- Wall to wall, ceiling to ceiling panel connection with cam-lock fastener type – Male & Female (above 75 mm thickness panel, industrial size, depending on Customer’s request with or without)

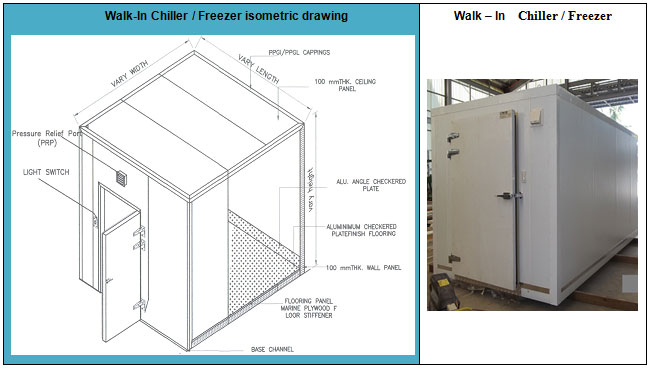

- Standard cam-lock spacing at the panel length ; above 2.6 m L panel = 1.5 m between cam-locks – Typical Customized WALK-IN Chiller / Freezer (for Commercial and Small scale application)

DYD — Polyurethane Insulated Panel Thermal Resistance (R-Value) Calculations

DYD — Polyurethane Insulated Panel Thermal Resistance (R-Value) Calculations

DYD — Polyurethane Insulated Panel Thermal Resistance (R-Value) Calculations

* Calculation formula of Thermal Resistance (R-Value)

| R-Value : 1/8(inner skin) +( )mm/1000/0.018 +1/20(outer skin) = ( ) m2 hr ºC/k cal |

<Table for P.U. panel R-Value by Thickness

| Thickness of Panel | Thermal Resistance Value (R-Value) | |

| Inches | MM | |

| 2 | 50 | 2.95 m2 hr ºC/k cal |

| 3 | 75 | 4.34 m2 hr ºC/k cal |

| 4 | 100 | 5.73 m2 hr ºC/k cal |

| 5 | 125 | 7.12 m2 hr ºC/k cal |

| 6 | 150 | 8.51 m2 hr ºC/k cal |

| 8 | 200 | 11.28 m2 hr ºC/k cal |

DYD — Polyurethane Insulated Panel ; U-value, weight, Cantilever, wall height Data

DYD — Polyurethane Insulated Panel ; U-value, weight, Cantilever, wall height Data

DYD — Polyurethane Insulated Panel ; U-value, weight, Cantilever, wall height Data

<Table – DYD panel data – The figure are based on 0.5 mm metal total thickness>

| Thickness (mm) | U-Value (W/m2) | Weight Kg/m2 | Ceiling element Span, cantilever as single span | Outside walls, bolts distance, Single span system wall height (m) | |

| Up to 8 m | Above 8 m | ||||

| 50 | 0.49 | 10.41 | 4.00 | 3.25 | 2.50 |

| 75 | 0.37 | 11.67 | 5.75 | 4.75 | 3.75 |

| 100 | 0.24 | 12.42 | 7.00 | 5.5 | 5.00 |

| 125 | 0.2025 | 13.3 | 8.125 | 6.13 | 5.56 |

| 150 | 0.16 | 14.45 | 9.00 | 7.00 | 6.00 |

| 200 | 0.12 | 16.42 | 10.00 | 7.50 | 6.50 |

DYD — Polyurethane Insulated Panel ; Kinds of Skin — coil outline

DYD — Polyurethane Insulated Panel ; Kinds of Skin — coil outline

DYD — Polyurethane Insulated Panel ; Kinds of Skin — coil outline

- Top coating of coil on the base steel substrate to be suitable for food processing purpose interior/exterior application

- PPGL – Pre-painted by polyester/ silicon polyester resin and aluminium/zinc alloy plated Galvalume

- PPGI – Pre-painted by polyester /silicon polyester resin Galvanized zinc plate Iron

- PVDF – Pre-painted by polyvinylidene Fluoride Galvalume or Galvanized Iron

- PVC Plastisol – Pre-painted by PVC Plastisol (100 to 200 ㎛ paint) GL or GI

- ABS (Acrylonitrile Butadiene Styrene – Synthetic Thermoplastic Polymer)skin

- Stainless Steel 304 skin – 0.5 to 0.8 mm Thickness, for Food Grade – Hygiene and , No-rusting purpose application

DYD — Polyurethane Insulated panel — Core foam — chemical specifications

DYD — Polyurethane Insulated panel — Core foam — chemical specifications

DYD – Polyurethane Insulated panel – Core foam – chemical specifications

- Outline of Characteristics of Polyurethane rigid Foam

- Polyurethane rigid foam consists of two main chemicals, mixing with blowing agent

- Main chemical A – Isocyanate (MDI)

- Main Chemical B – Polyol with various catalysts pre-mixed

- Blowing agent (Cyclo-Pentane, R-141B until phase out in year 2015)

- Polyurethane rigid foam is composed of independent closed fine cells by 90 -95% which provides the lowest “K” and highest “R” factors – lowest thermal conductivity.

- Lowest thermal conductivity and best thermal stability

- Light weight and high strength to weight ratio insulated material

- Most energy and cost efficient insulation martial currently available

- Excellent adhesion to most substrate materials

- Thanks to the unique characteristics of Polyurethane rigid foam is for ideal application of cold storages, freezers, and various and wide range of temperature control facilities.

- Polyurethane rigid foam consists of two main chemicals, mixing with blowing agent

- Properties of Polyurethane rigid foam

| Properties | Unit | Data |

| Density | Kg/m3 | 40 – 45 |

| Thermal Conductivity | Kcal / m h ºC | 0.016 – 0.018 |

| Compressive Strength | Kd/m2 | 1.5 – 3 |

| Water absorption | % | Below 2 |

| Closed cell content | % | 95 |

| Fire class | Grade | B2/B3 |

| Application temp. range | ºC | -180 to +100 |

<DYD –Rigid PU Foam has been achieved Density certificates from 3rd laboratories / Fire class “B3” self extinguishing materials>

DN CORPORATE CENTER 7th Floor Unit B, 1388 Quezon Avenue Brgy, South Triangle Quezon City.

DN CORPORATE CENTER 7th Floor Unit B, 1388 Quezon Avenue Brgy, South Triangle Quezon City.  Refrigeration Systems

Refrigeration Systems